|

Processing of color reversal film

ORWOCHROME - Process 9165

(I) Steps of processing.

| |

Steps |

Solution |

Time (minutes) |

Temperature (șC) |

| 1 |

Black-and-White Development |

ORWOCOLOR 07 |

5-12 |

25 ±0.25 |

| 2 |

Rinse |

|

1 |

12-15 |

| 3 |

Stop Bath |

ORWOCOLOR 37 |

2 |

23-25 |

| 4 |

Rinse |

|

5 |

12-15 |

| 5 |

Re-exposure |

|

2-5 |

- |

| 6 |

Color Developement |

ORWOCOLOR 17 |

10-12 |

25 ±0.25 |

| 7 |

Rinse |

|

20 |

12-15 |

| 8 |

Bleach |

ORWOCOLOR 50/2 |

5 |

23-25 |

| 9 |

Rinse |

|

5 |

12-15 |

| 10 |

Fixing |

ORWOCOLOR 71 |

5 |

23-25 |

| 11 |

Rinse |

|

15 |

12-15 |

| 12 |

Wetting Agent |

R905* (1+200) |

0.5 |

23-25 |

| 13 |

Drying |

|

- |

max. 40 |

(II) Formulas

ORWOCOLOR 07 - Black-and-White

Developer

1.

Sodium hexametaphosphate ....................... 2.0 g

2.

Sodium sulfite .......................................... 40.0 g

3.

Sodium tetraborate .................................. 15.0 g

4.

Hydroquinone ........................................... 4.5 g

5.

Fenidone ................................................. 0.25 g

6.

Potassium carbonate ................................ 30.0 g

7.

Potassium bromide .................................... 2.0 g

8.

Potassium thiocyanate ................................ 2.0 g

9.

Potassium iodide .................................... 0.007 g

10.

Water to make ........................................... 1 L

pH = 10.0-10.2

ORWOCOLOR 37 -Stop

Solution

1.

Sodium acetate ........................................ 15.0 g

2.

Acetic acid, glacial ................................... 25 mL

3.

Water to make ............................................. 1 L

pH = 4.0-4.4

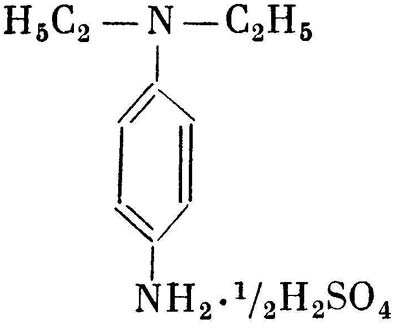

ORWOCOLOR 17 - Color

Developer

1.

Sodium hexametaphosphate .......................... 3.0 g

2.

Hydroxylamine sulfate ................................... 1.5 g

3.

N,N-diethyl p-phenylene diamine sulfate**..... 4.0 g

4.

Potassium carbonate ................................... 75.0 g

5.

Sodium sulfite ............................................... 3.0 g

6.

Potassium bromide ........................................ 2.0 g

7.

Water to make ................................................ 1 L

pH = 10.8-11.0

ORWOCOLOR 50/2 - Bleaching Solution

1.

Potassium ferricyanide ................................. 65.0 g

2.

Potassium bromide ...................................... 25.0 g

3.

Sodium thiocyanate ...................................... 27.0 g

4.

Acetic acid, glacial ...................................... 3-7 mL

5.Water to make .................................................. 1 L

pH = 5.2 ± 0.2

ORWOCOLOR 71 - Fixing

Solution

1.

Sodium thiosulfate, anhydrous ................... 128.0 g

2.

Water to make ............................................... 1 L

pH = 7.5 ± 0.3

ORWOCOLOR 73 - Fixing Solution

1.

Sodium thiosulfate, anhydrous .................. 120.0 g

2.

Ammonium chloride ................................... 80.0 g

3.

Water to make ............................................... 1 L

Notes:

* R905 wetting agent is

manufactured by Calbe Chemie under the name of Calbe F905 Netzmittel.

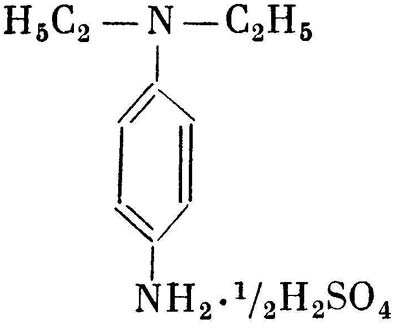

** The color developing agent

N,N-diethyl p-phenylene diamine sulfate is a phenylenediamine

derivative:

(III) Consulted documents:

|