I opened my first cartridge in daylight with a saw…

Everybody developing Super 8 films on their own sooner or later faces the task of opening the Super 8 cartridge to get the film into the development tank. The latter goes with some practice, the Lomo tank and a turntable in less than 30 seconds. When opening cartridges, opinions differ: Some break the ratchet inside the cartridge by a counterclockwise 360° turn and then pull the film out of the cartridge. Others, (to which I belong) open the cartridge and take the film wind out all over, and load it into the Lomo reel.

Possible ways to open a cartridge:

- Sawing it open

- With side cutters or pliers, the flange cracking off

- Stem up with hammer and screwdriver

- With bare hands (goes well with very old revues and agfas)

- With the Kodak Super 8 cartridge opener

The best and fastest way:

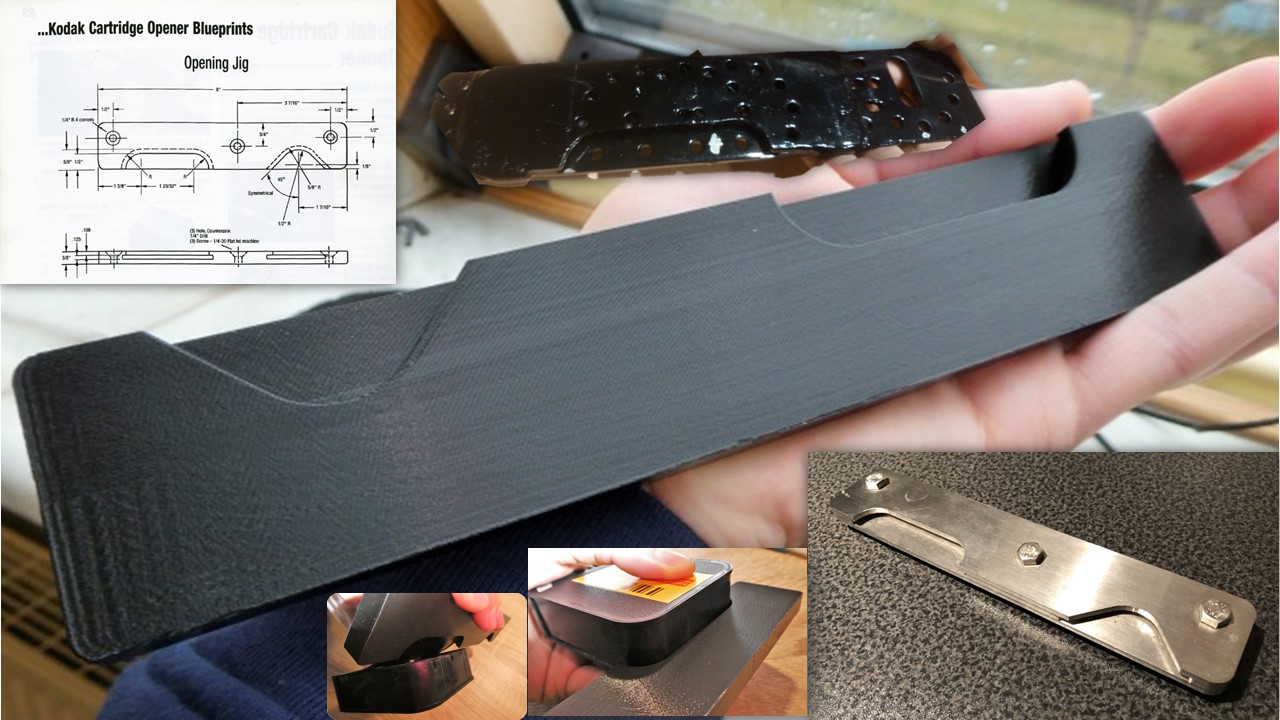

From Kodak there is a guide, or rather a technical drawing of a Super 8 cartridge opener. I built this myself successfully at first. Unfortunately, opening never works the first time, as it hasn’t become as accurate as I had planned. The stainless steel original does its service excellently on the first or second start.

How exactly does it work? First of all, one should know that a Super 8 cartridge consists of two large plastic parts, the centerpiece where the film is guided and ‘book cover’ piece that closes everything light-tight. At the top of the cartridge, where the label is glued on, this lid is “inserted”, we don’t have to get to that compartment. At the bottom, where the winding core can be seen, the “book lid” stands over the middle part of the cartridge and forms a flange. If this flange is properly broken off (so that the bonding breaks open), you can simply unfold the cassette from below and take the film-wind out. The opener breaks this flange and/or the glue. The cartridge is pushed into its corresponding recess and cracked down with a quick move. 35mm film canisters can also be opened with the opener. For the exact application, a video will follow here later.

The technical drawing becomes a 3D model:

Because CNC milling or water steel cutting is not an option for cost reasons, the opener is to be 3D printed, another hobby of mine. That I can switch my CAD program to inch was a very large work facilitation that saved me the constant conversion to centimeters. The three overlying, required parts were created after some time. Since there were a few measurements missing from the recess for sound cartridges (or 35mm film canisters), I had to make some considerations and calculations in order to get to the dimensions needed.

I printed out the recesses for Super 8 cassettes and 35mm film canisters for testing to check that everything fits in from the measurements. The Super 8 slot fit right away, the 35mm film slot had to be made a little higher so that the canister fits in and can also be opened without any problems.

You can download the instruction/technical drawing here.

Here you can find the stl files. Download my files.

My printer is too small : ́(

To get around this problem, I paid €15.16 including postage to get the part professionally printed by a nearby service provider. I find it amazing how cheap the prices are, considering print time and material consumption.

The practical test:

After just 7 days, my opener was delivered and tested immediately. It works just as well as it does in the initial tests and magnitudes better than my self-built variant. Thanks to the solid print, it holds out the forces that arise perfectly and will not break them. The only thing I am worried about is the recess for the 35mm film canisters is because the metal of the cartridge scratches on the plastic. It may therefore be that sooner or later this slot will become unusable due to wear and tear. But this is only evident in the long run, as I develop very few 35mm. Also, there are bottle openers… And actually, that corner cutout was meant for sound cartridges, only, who has such today …

Opening 35mm film canisters, too, succeeds with some practice.

A YouTube video about the opener will be linked here soon.

Related Posts